Natural gas provides 37% of the energy used by Australian manufacturers1,

Australian manufacturing supports around 1.3 million jobs and contributes

more than $100 billion to the national economy2.

NATURAL GAS IS USED BY INDUSTRY FOR HIGH-HEAT APPLICATIONS3

Steel Bricks Cement Cardboard Plastics Paper Mining andcritical minerals Building

products

INDUSTRIAL ENERGY NEEDS PROVIDED BY GAS, BY SECTOR (%)

Ceramics Textiles and clothing Glass and glass products Chemicals Mining Basic non-ferrous metals Cement and concrete All Australian manufacturing Paper and cardboard 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%Source: Australian Energy Update 2024, Table F

Natural Gas Is Helping To Fuel Australian Construction

Many Australian manufacturers use natural gas to process and add value to natural resources like bauxite, clay and silica sand by making these into everyday products such as aluminium, bricks and glass used to build homes and buildings across the country.

FROM AUSTRALIAN CLAY TO AUSTRALIAN BRICKS

Bricks are made using clay quarried from surface deposits. The clay is crushed and mixed with materials like shale, sand, lime and colourants to achieve the desired consistency and properties.

Bricks are made using clay quarried from surface deposits. The clay is crushed and mixed with materials like shale, sand, lime and colourants to achieve the desired consistency and properties.

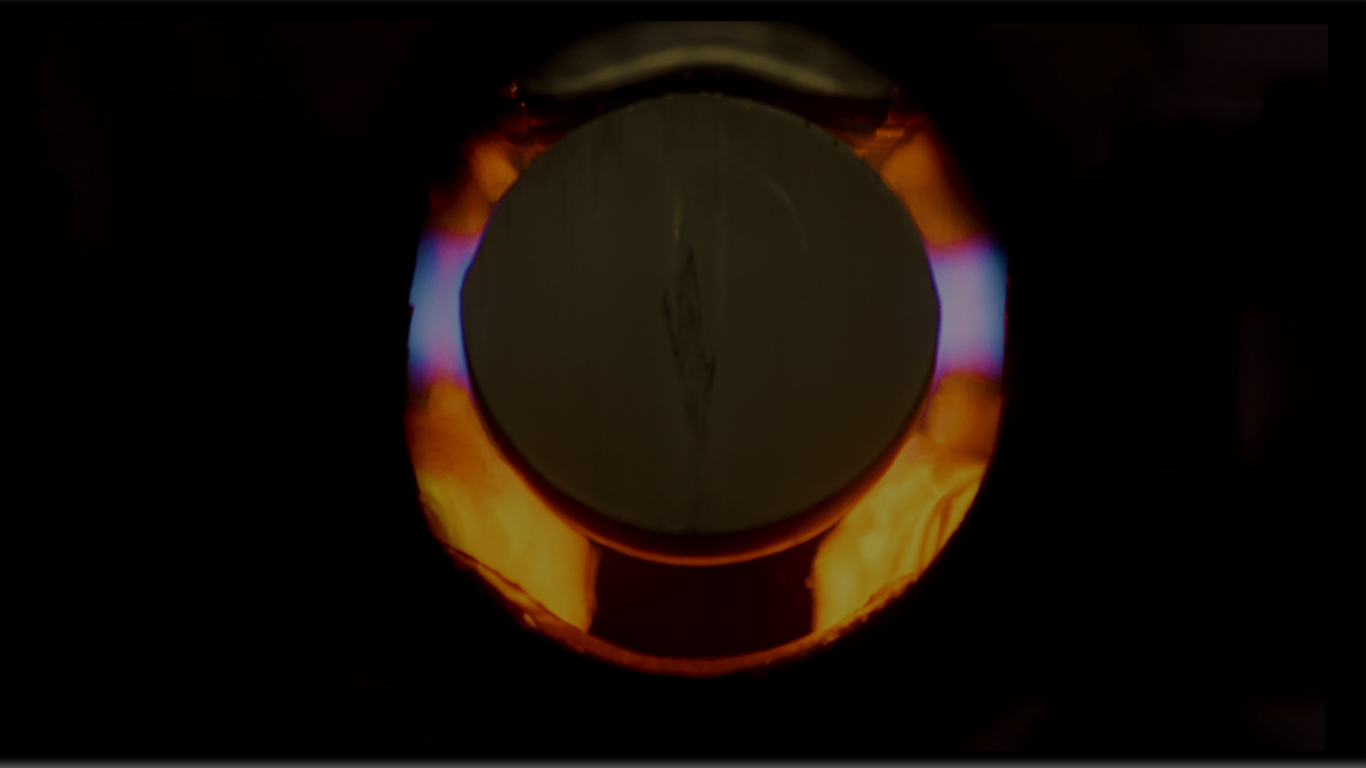

The clay mixture is shaped, air dried and loaded into gas-fired kilns at temperatures up to 1200°C.

After firing, the bricks are cooled and made ready to be used in the construction of home and other structures.

FROM AUSTRALIAN BAUXITE TO AUSTRALIAN ALUMINIUM

Australian bauxite contains alumina - the key mineral used to create aluminium.

Australian bauxite contains alumina - the key mineral used to create aluminium.Once mined and taken to a processing plant, the bauxite is crushed and mixed with a hot solution of sodium hydroxide (caustic soda) that dissolves the alumina inside it.

The dissolved alumina is is then filtered into a powder, subjected to electrolysis and then formed into molten aluminium before being cast into ingots.

Gas-fired furnaces are used to maintain the high temperatures required for this process.

The ingots are further processed (again using gas-fired furnaces) into various aluminium products like window and door frames.

FROM AUSTRALIAN SILICA SAND TO AUSTRALIAN GLASS

After mining, silica sand is taken to a processing plant. Refined silica sand is mixed with raw materials like soda ash, limestone, or recycled glass.

After mining, silica sand is taken to a processing plant. Refined silica sand is mixed with raw materials like soda ash, limestone, or recycled glass.

This mixture is heated in a gas-fired furnace at temperatures exceeding 1700°C to melt the sand mixture and form molten glass.

During this process, the gas-fired furnace provides a consistent and controllable heat source, essential for producing high-quality glass.

Once molten, the glass is shaped into sheets, cooled, and cut to size ready for use in windows and doors in home and buildings.

Australian manufacturing relies on natural gas to provide the consistent, extreme temperatures required to transform raw materials into durable building products whilst also supporting thousands of Australian jobs.